Blue VCSELs

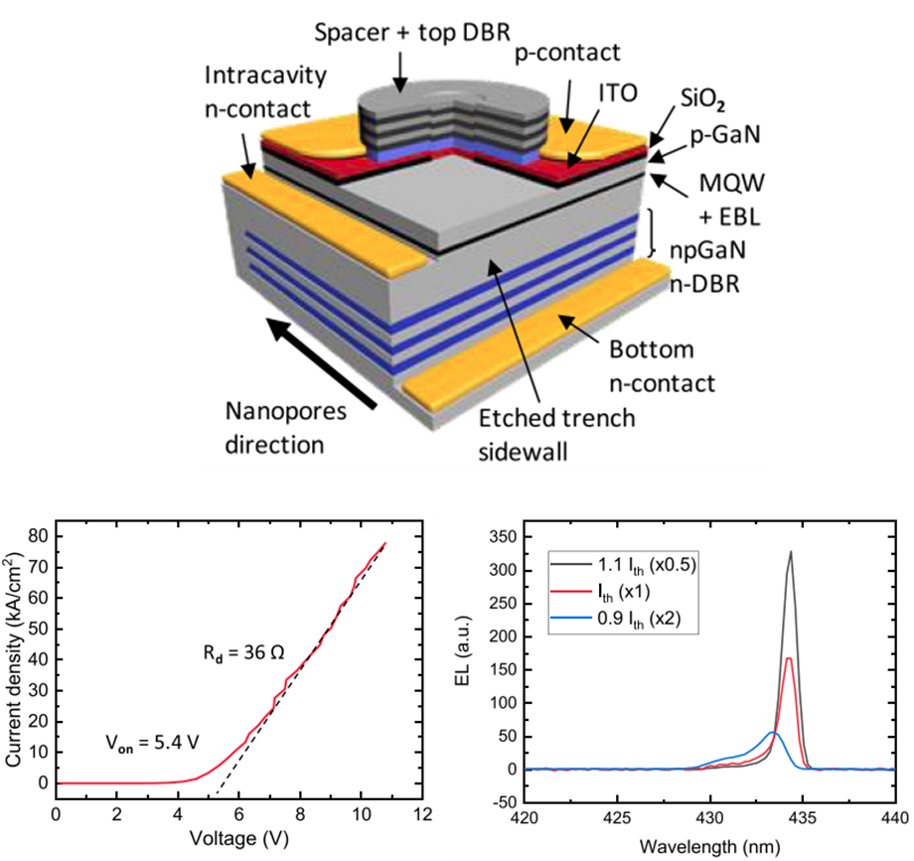

We have developed a novel conductivity based selective electrochemical etching to introduce nanometer sized pores into GaN. By controlling the doping and electrochemical etching bias, we are able to control the pore morphology. The nanoporous (NP) GaN can be considered a new form of GaN with an unprecedented tunability in optical index. We show the potential of this NP-GaN to overcome the optical and epitaxial limitations of AlGaN, which has been the bottleneck for GaN-based laser diodes for decades. The advantage of NP-GaN for vertical surface-emitting laser diodes (VCSELs) is that NP-GaN works as low refractive index material that is lattice-matched to GaN. We successfully demonstrated room-temperature pulse-operation of blue NP VCSELs under electrical injection.