|

|

Additive Manufacturing Techniques |

|

|

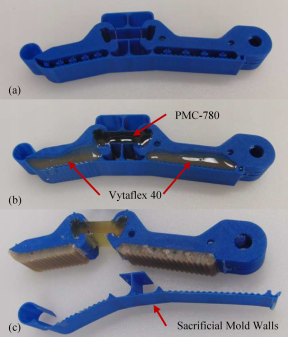

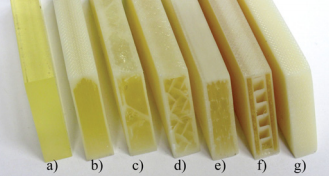

Advances in rapid-prototyping (RP), such as 3D printing, or AM, have enabled the efficient fabrication of complex components that would otherwise be very difficult to make through conventional means. To date, this has had the most profound impact on the iterative design process for prototypes, but researchers have also applied RP processes toward producing functional assemblies.The limited selection of material properties has been the primary limitation of AM, especially for the more widely available FDM machines, which are restricted to thermoplastics such as acrylonitrile butadiene styrene (ABS), polyactic acid (PLA), polycarbonate, and nylon. In order to expand the utility of current desktop AM processes, we explore techniques that expand the capabilities of AM parts, by marrying them with other readily available materials to improve their strength, functionality, and other mechanical properties.

Sample Publication:

Raymond R. Ma, Joseph T. Belter, and Aaron M. Dollar

Hybrid Deposition Manufacturing: Design Strategies for Multi-Material Mechanisms via 3D-Printing and Material Deposition, ASME Journal of Mechanisms and Robotics, vol. 7(2), 021002, 2015.

Fabrication Techniques

2015

All Fabrication Techniques Publications >>

|