My research is focused on the development of scalable lithographic techniques for the directed assembly of functional materials.

High Resolution Nanoimprint of Organic Photovoltaics with Bulk Metallic Glass Molds (with Jan Schroers’ Group)

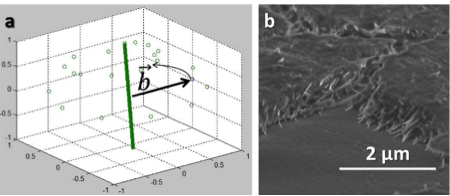

Bulk metallic glass (BMG) materials have been demonstrated as effective for the inverted replication of hard templates by hot embossing above their glass transition temperature. Additionally, BMG molds so produced have been themselves used as nanoimprint dies by the transfer of these replicated features to similarly softenable materials. As imprint materials, BMGs ability to both act as a moldable material and an imprint die places it in comparison to both typical hard die materials (e.g. silicon) and also soft stamping materials (e.g. PDMS). While BMG dies have been utilized to imprint polymeric materials, these studies have not yet pushed the limits of imprint beyond what could be easily performed by, for example, PDMS stamping, let alone highlighting the unique abilities of BMGs as a die material. For example, high-aspect ratio, sub-100 nm imprint of 2D structures has not yet been shown. We have demonstrated sub-nm imprint of high aspect-ratio structures into an active polymeric materials. Figure 1 shows imprint of both poly(3-hexylthiophene-2,5-diyl) (P3HT) and mixtures of P3HT with Phenyl-C61-butyric acid methyl ester (PCBM)) with applications in ordered bulk heterojuction (OBHJ) photovoltaic devices. OBHJ structures formed of semiconductor polymers are one potential area where the ability to imprint high aspect ratio nanostructures is highly desirable. Ideal OBHJ sample geometries consist of domain sizes for the donor and acceptor phases commensurate to twice the exciton diffusion length (~30 nm) and thicknesses on the order of hundreds of nm, dimensions that are clearly accessible to BMG imprint. [4]

Figure 1: Tilted SEM images of (a) a BMG mold of hexagonally arrayed nanorods and (b) a fracture surface of the resulting imprint in a mixture of P3HT and PCBM.

Solution Processing of Ordered Thin Film Nanowire Composites by Magnetic Field Alignment

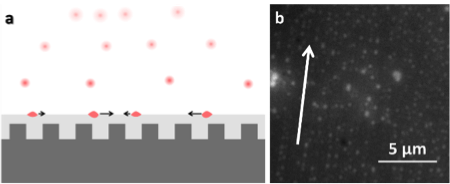

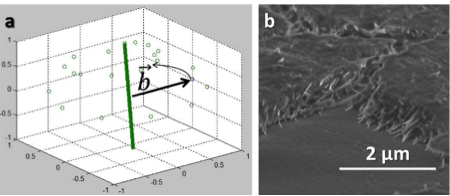

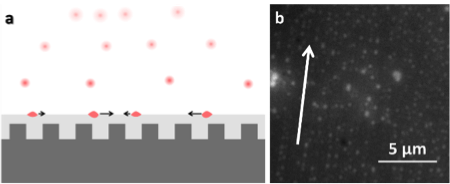

Vertically aligned nanowire forests are a desirable geometry for many applications, including as electrodes, heterojunctions, and high surface energy interfaces. Most conventional aligned nanowire structures, however, are generated by methods that require (i) high temperatures, (ii) a specific substrate, or (iii) high cost lithographic techniques. We seek to utilize the magnetic alignment of nanowires to enable the solution processing of thin films of aligned nanowire-polymer composites on a generalized substrate at a fraction of the cost of other methods. The inclusion of polymer in the wire solution, we can both control the areal density and also incorporate additional functionalities to the final composite device. As an example, the use of a conjugated polymer (such as P3HT) allows for the final structures to act as inorganic-organic ordered heterojunction solar cells. Based on simulations, the ability to field-align negatively anisotropic particles of a given size can best occur at an optimized balance of field strength and solution viscosity (Figure 2a). This could be readily controlled using a thermal resist, which allowed for controlled, rapid solidification of an initially high-viscosity system, leading to high degree of alignment. Generating functional thin films by slow evaporation, however, leads to the solution passing through many values of viscosity and also possesses other drying forces that lead to misalignment. Through control of the evaporation rate, surface properties of the evaporating solution, and wire quality, we are able to obtain aligned sub-micron films of wires in P3HT over a large area (Figure 2b). We are currently in the process of continued optimization and have begun to fabricate organic photovoltaic devices.

Figure 2: (a) Simulation of magnetic nanowire alignment by a rotating magnetic field where the green dots represent the alignment history of the wire. (b) Tilted SEM image of a fracture surface of an aligned, sub-micron nanowire composite generated by solvent evaporation.

Scalable Directed Assembly of Electrosprayed Nanoparticles by Durotaxis (with Eric Dufresne’s Group)

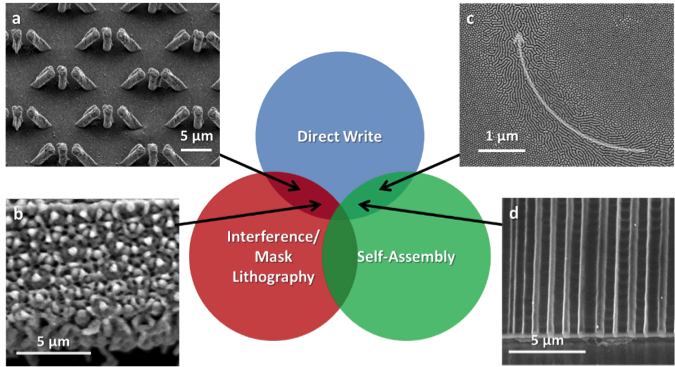

Despite the ever-growing library of fabrication techniques, achieving scalability in the deliberate deposition of nanoparticles remains a challenge. Nanotransfer printing, analogous to ubiquitous, large scale printing, is a very attractive potential solution, as it allows for definition of a patterning master that possesses all of the features of the final patterned device that can be used for the generation of many devices. The positioning of particles on the master, however, is non-trivial and the expensive masters may be damaged through mechanical contact between with the particles and the two surfaces during transfer. We have demonstrated a method for the positioning of nanoparticles though a combination of liquid durotaxis and electrospray. Durotaxis describes the phenomenon wherein liquid droplets on flat, soft surfaces spontaneously move towards softer, or deeper, regions of the surface due to changes in the effective contact angle. In this way, the droplets can mimic an underlying pattern, which has been demonstrated recently as a method of driving the condensation of water droplets on the sub-mm scale. To extend this concept to the sub-micron scale, we have utilized electrospray as a technique for delivering microdroplets carrying dilute quantities of a target material (e.g. dye, polymer, and nanoparticles), which when deposited on a patterned hard substrate (here, a rigid plastic) coated by a soft overlayer (here, a silicone elastomer) that is not swollen by the solvent, are directed towards the thicker regions of the elastomeric layer during their evaporation. As a result, the materials transported within the droplets are deposited in a spatially controlled manner (Figure 3). The final resulting pattern requires no direct patterning of the particles beyond the large-area electrospray and therefore represents a high-throughput technique. Additionally, the particle assembly has the benefit of being generated on a flat, conformable surface on a flexible patterned substrate. This latter factor is advantageous as it both allows for subsequent transfer printing of the materials and protects the underlying pattern from potentially damaging mechanical contact with the particles and transferred substrate, increasing its usable lifetime. This greatly increases the potential for scaling to a reel-to-reel process.

Figure 3: (a) Schematic of directed assembly of loaded microdroplets by combined electrospray and durotaxis. (b) Fluorescence microscopy of dye nanoparticles directed by an underlying grating.

|

- Hu, H.; Singer, J. P. ; Osuji, C. O.; Morphological Development in Thin Films of a Lamellar PS-b-P4VP Block Copolymer Deposited by Electrospray , Macromolecules, 47, 16, 5703-5710, 2014. DOI: 10.1021/ma500376n

- Pelligra, C. I.; Huang S.; Singer, J. P. ; Mayo, A.; Mu, R. R.; Osuji, C. O.; High-Fidelity Solvothermal Growth of Arrayed ZnO Nanorods with Controlled Diameter and Spacing Using Block Copolymer Templates , Small, 10, 21, 4304-4309. DOI:10.1002/smll.201400956

- Singer, J. P. ; Gotrik, K. W.; Lee, J.-H.; Kooi, S. E.; Ross, C. A.; Thomas, E. L.; Alignment and Reordering of a Block Copolymer by Solvent-Enhanced Thermal Laser Direct Write , Polymer, 55, 7, 1875-1882, 2014. DOI:10.1016/j.polymer.2014.02.028

- Lee, J.-H.; Koh, C. Y.; Singer, J. P. ; Jeon, S.-J.; Maldovan, M.; Stein, O.; Thomas, E. L.; 25th Anniversary Article: Ordered Polymer Structures for the Engineering of Photons and Phonons , Advanced Materials, 26, 4, 532-569, 2013. DOI:10.1002/adma.201303456

- Singer, J. P. ; Lin, P.-T.; Kooi, S. E.; Kimerling, L. A.; Jurgen, M.; Thomas, E. L.; Direct-Write Dewetting of Polymer Thin Films by a Laser-Induced Thermal Gradient , Advanced Materials, 25, 42, 6100-6105, 2013 . DOI:10.1002/adma.201302777

- Lee, J.-H.; Veysset, D.; Singer, J. P. ; Retsch, M.; Saini, G.; Pezeril, T.; Nelson, K. A.; Thomas, E. L.; Dynamical Responses of Layered Nanostructure Composites at High Strain Rate Deformation , Nature Communications, 3, 1164, 2012. DOI:10.1038/ncomms2166

- Lee, J.-H.; Singer, J. P. ; Thomas, E. L.; Micro-/Nano-Structural Materials as Mechanical Meta-Materials , Advanced Materials, 24, 36, 4782-4810, 2012. DOI:10.1002/adma.201201644

- Singer, J. P. ; Lee, J.-H.; Kooi, S. E.; Thomas, E. L.; Rapid Fabrication of 3D Terahertz Split Ring Resonator Arrays by Novel Single-Shot Direct Write Focused Proximity Field Nanopatterning , Optics Express, 20, 10, 11097-11108, 2012. DOI:10.1364/oe.20.011097

- Singer, J. P. ; Kooi, S. E.; Thomas, E. L.; Focused Laser Spike (FLaSk) Annealing of Photoactivated Chemically Amplified Resists for Rapid Hierarchical Patterning , Nanoscale, 3,7, 2730-2738, 2011. DOI: 10.1039/c1nr10050e

- Zhang, G.; Singer, J. P. ; Kooi, S. E.; Evans, R. E.; Thomas, E. L.; Fraser, C. L.; Reversible Solid-State Mechanochromic Fluorescence from a Boron Lipid Dye , Journal of Materials Chemistry, 21, 23, 8295-8299, 2011. DOI:10.1039/c0jm03871g

- Singer, J. P. ; Meyer, M. S.; Speer Jr., R. M.; Fischer, J. E.; Pinkerton, F. E.; Determination of the Phase Behavior of (LiNH2)c(LiBH4)1-c Quaternary Hydrides through in Situ X-ray Diffraction , Journal of Physical Chemistry C, 113, 43, 18927-18934, 2009. DOI:10.1021/jp905970h

- Osswald, S.; Portet, C.; Gogotsi, Y.; Laudisio, G.; Singer, J. P. ; Fischer, J. E.; Sokolov, V.V.; Kukushkina, J. A.; Kravchik, A. E.; Porosity Control in Nanoporous Carbide-Derived Carbon by Oxidation in Air and Carbon Dioxide , Journal of Solid State Chemistry, 182, 7, 1733-1741, 2009. DOI:10.1016/j.jssc.2009.04.017

- Yeon, S. H.; Osswald, S.; Gogotsi, Y.; Singer, J. P. ; Simmons, J. M.; Fischer, J. E.; Lillo-Rodenas, M. A.; Linares-Solano, A.; Enhanced Methane Storage of Chemically and Physically Activated Carbide-Derived Carbon , Journal of Power Sources, 191, 2, 15, 560-567, 2009. DOI:10.1016/j.jpowsour.2009.02.019

- Kim, H. S.; Singer, J. P. ; Gogotsi, Y.; Fischer, J. E.; Molybdenum Carbide-Derived Carbon for Hydrogen Storage, Microporous and Mesoporous Materials, 120, 3, 267-271, 2009. DOI:10.1016/j.micromeso.2008.11.019

- Singer, J. P. ; Mayergoyz, A.; Portet, C.; Schneider, E.; Gogotsi, Y.; Fischer J. E.; Enhanced Volumetric Hydrogen Storage Capacity of Porous Carbon Powders by Forming Peels or Pellets, Microporous and Mesoporous Materials, 116, 469-472, 2008. DOI:10.1016/j.micromeso.2008.05.005

- Dash, R. K.; Chmiola, J.; Yushin, G.; Gogotsi, Y.; Laudisio, G.; Singer, J. P. ; Fischer, J. E.; Kucheyev, S.; Titanium Carbide Derived Nanoporous Carbon for Energy-Related Applications, Carbon, 44, 12, 2489-2497, 2006. DOI:10.1016/j.carbon.2006.04.035

- Laudisio, G.; Dash, R. K.; Singer, J. P. ; Yushin, G.; Gogotsi, Y.; Fischer, J. E.; Carbide-Derived Carbons: A Comparative Study of Porosity Based on Small-Angle Scattering and Adsorption Isotherms, Langmuir, 22, 21, 8945-8950, 2006. DOI:10.1021/1a060860e

- Shao, Z.; Singer, J. P. ; Liu, Z.; Liu, Y.; Li, H.; Osuji, C. O.; Schroers, J.; Shear Accelerated Crystallization in a Supercooled Atomic Liquid, Manuscript in submission, arXiv:1407.2078.

- Singer, J. P. ; Gopinadhan, M.; Shao, Z.; Taylor, A. D.; Schroers, J.; Osuji, C. O.; High-Resolution Nanoimprint of Functional Polymers with Bulk Metallic Glass Molds, Manuscript in submission.

- Singer, J. P. ; Pelligra, C. I.; Korblum, N.; Gopinadhan, M.; Ketkaew, J.; Schroers, J.; Osuji, C. O.; Nanotexturing of Amorphous Metals through Sacrificial Templates, Manuscript in preparation.

- Singer, J. P. ; Kooi, S. E.; Thomas, E. L.; Influence of Materials Properties on Laser Spike-Induced Dewetting of Polymer Thin Films, Manuscript in preparation.

|