|

|

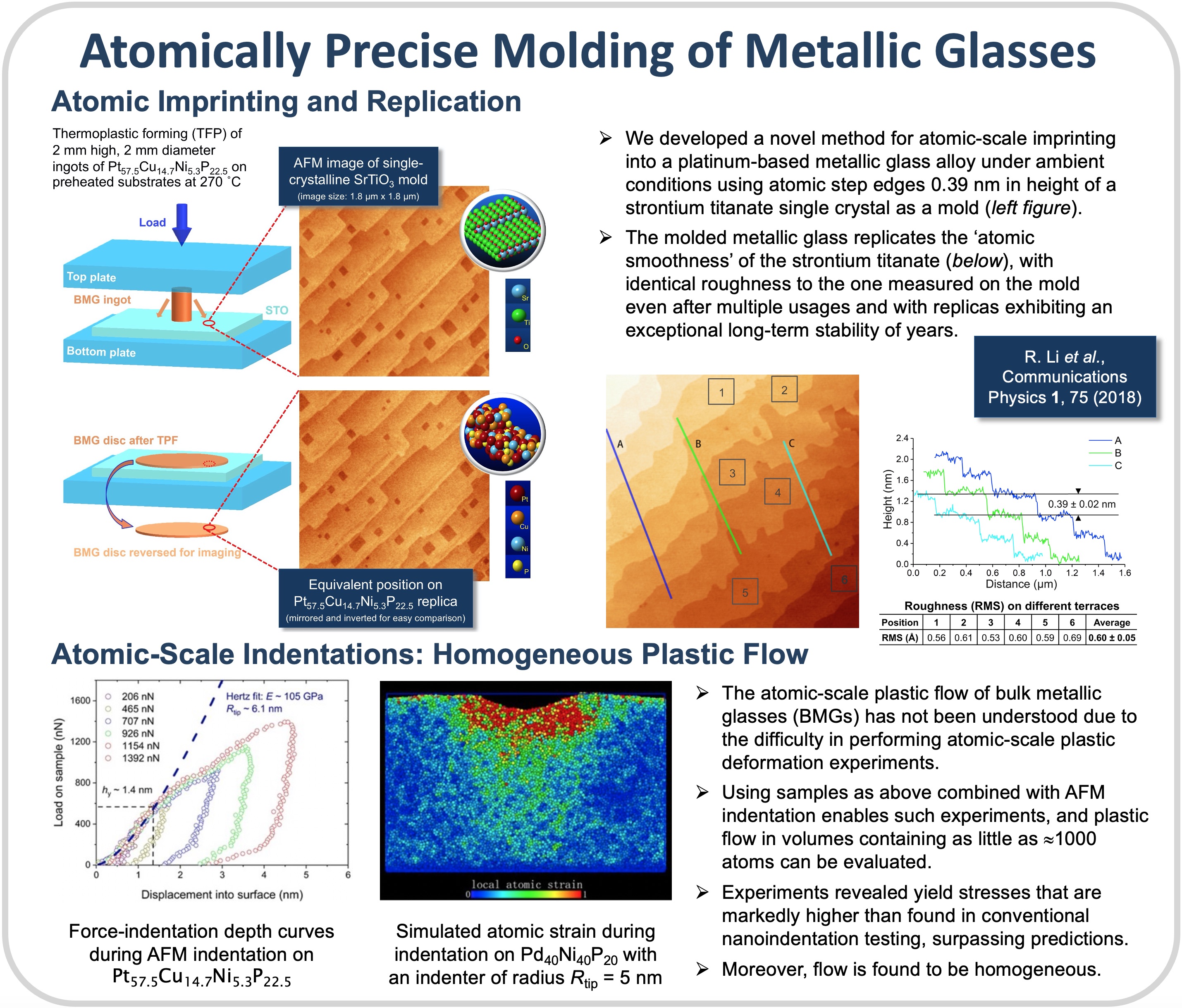

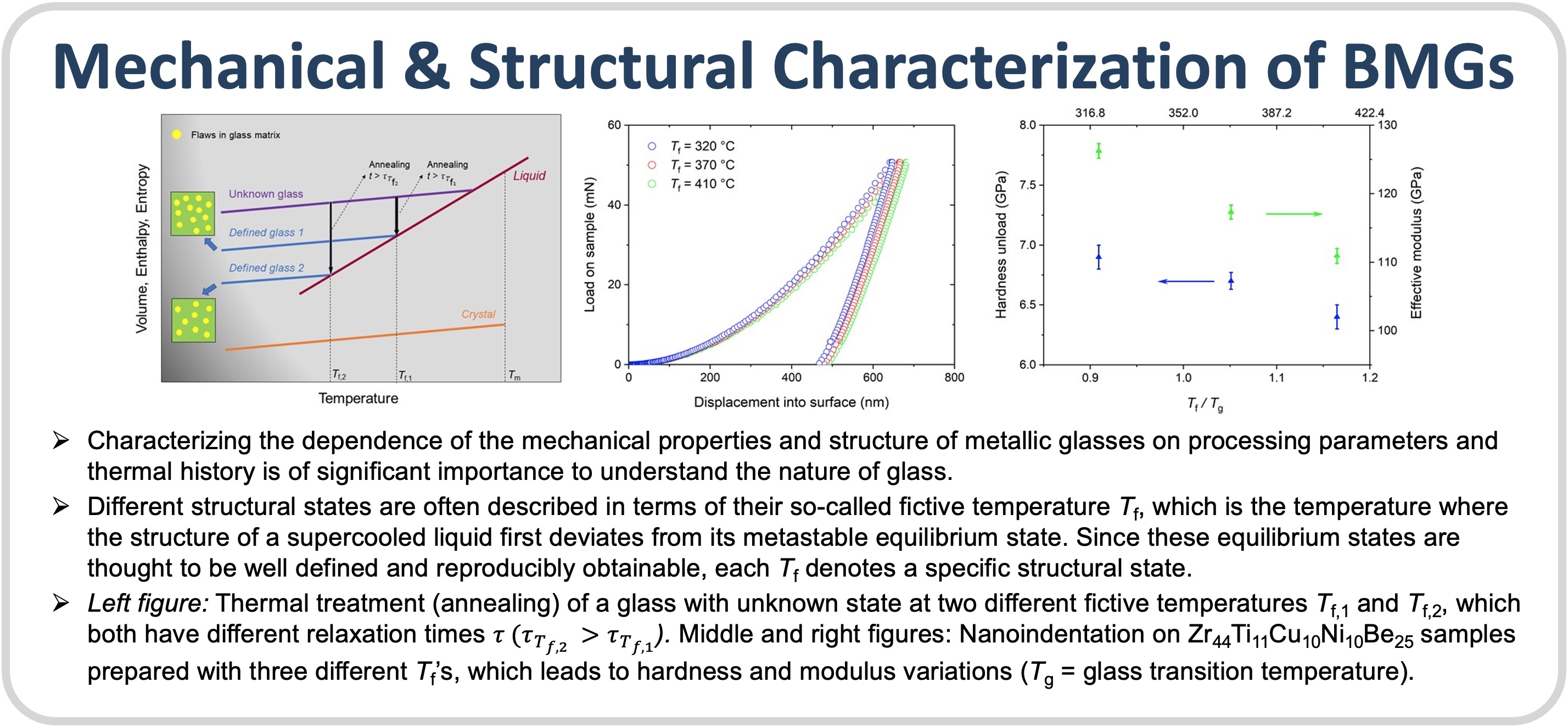

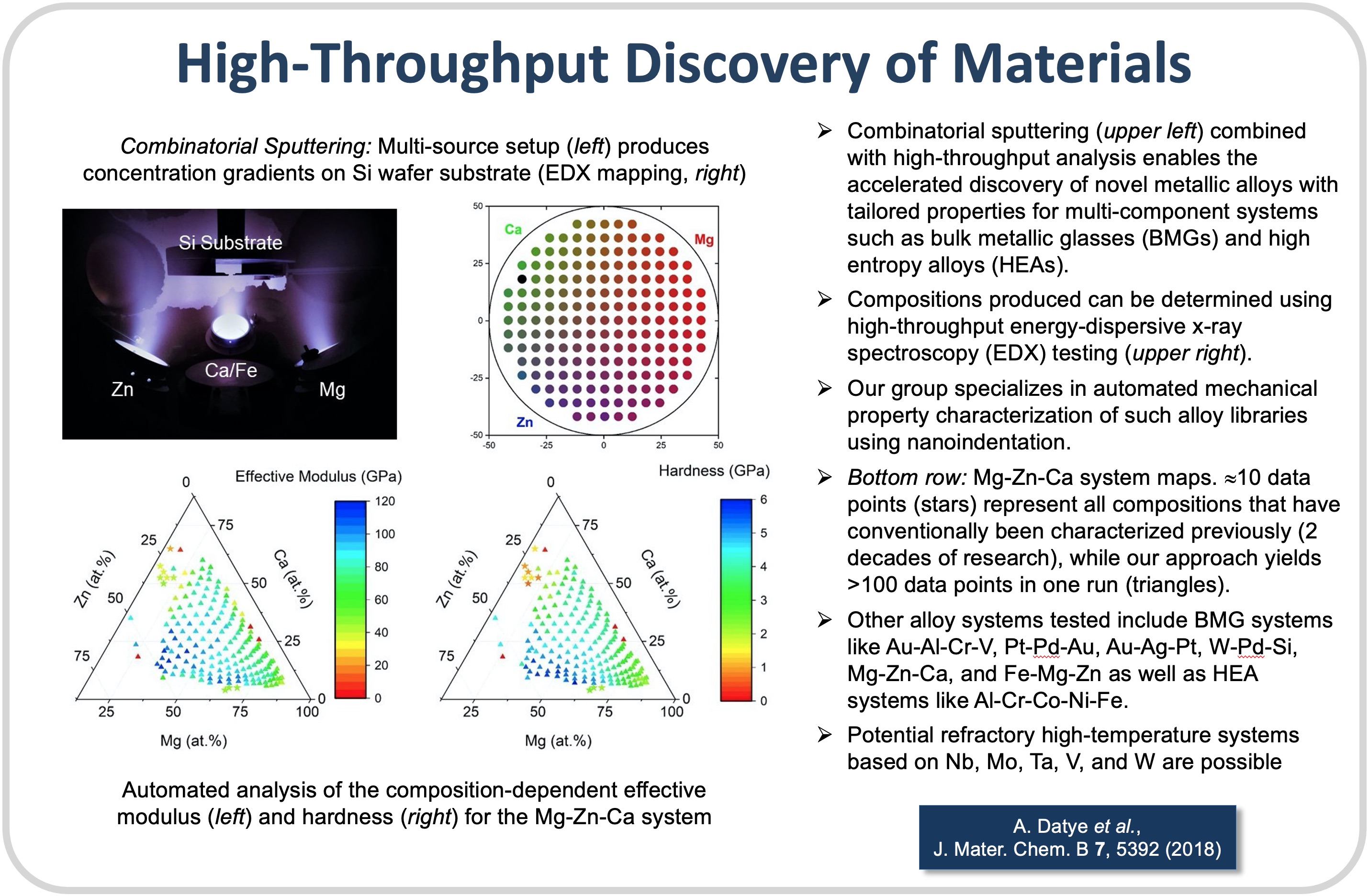

Nanomechanical Research and Materials DiscoveryThis activity revolves around experiments designed to study the structure, formability, and preparation-dependent mechanical properties of metallic alloys with a focus on bulk metallic glasses. While many standard measurements such as differential scanning calorimety (DSC), scratch and tensile testing, or density measurements using pycnometry are routinely being performed, we in particular specialize on nanometer-scale elasticity, hardness, and plastic flow measurements using nanoindentation and atomic force microscopy-based indentations. To obtain reliable results from experiments where only few atoms are displaced, we have developed techniques for atomically precise molding of metallic glasses that lead to surfaces with a roughness of significantly below one angstrom, or a fraction of an atomic diameter. These techniques may also be used to fabricate surface structures for electrical, optical, and biological applications with atomic precision. In addition, nanoindentation is applied to the high-throughput discovery of materials with optimized mechanical properties using materials libraries produced by combinatorial sputtering. Below, some of these activities are illustrated with examples.

|

|